Written by Ann Nordby for BBE

At the end of the first "Back to the Future" film, Doc Brown throws a handful of banana peels into the "Home Fusion biofuel burner" on the back of his Delorean time machine to power his take-off into 2015. That scenario hasn't come true yet: we're not using biowaste as fuel for everyday life. But a group of University of Minnesota scientists is working on it.

Decarbonization is the current theme of Professor Shri Ramaswamy's Biobased Process and Products Engineering lab. The lab has already made progress with decarbonizing the production of paper. Funded by a three-year, $3 million grant from the United States Department of Energy, the project partners include Savannah River National Lab (SRNL), Electric Power Research Institute (EPRI) and Rapid Process Intensification and Deployment (RAPID) Institute and the US paper industry.

Paper production is a heat-intensive process that relies partly on natural gas or coal-based steam. The team is figuring out how to add acoustic and electromagnetic energy to the drying process. These innovations aim to reduce the carbon footprint of paper by 20-25%. If adopted broadly, the impact will be huge, since paper shrouds everything from breakfast cereal to Amazon deliveries.

Since 2021, the lab has also been working on a grand challenge issued by the US Department of Energy: how to produce sustainable aviation fuels (SAF) on a commercial scale. The US Department of Energy has set a goal of decarbonizing jet fuel by 2050. Ramaswamy and his team won the $3.5 million grant together with industry partners ADM, GEVO and Argonne National Laboratory.

Aviation accounts for about 2% of CO2 emissions globally. But that percentage will rise as the number of electric vehicles on the roads overtakes those with petroleum engines. Electric engines are not viable for jets, so researchers are exploring possible fuel solutions.

One of these is bio (organic) waste-derived jet fuels. Ramaswamy says this approach could decarbonize the process in three ways. The first, it substitutes biofuels for fossil fuels. This is not new – most car owners are already familiar with E85, an auto fuel that includes ethanol, made from corn. The aviation industry is pursuing a similar approach.

The second benefit is that using bio (organic) waste, such as yard clippings or crop stubble, is better than using food or feed crops. That process has a carbon footprint of its own. But like corn-based ethanol, bio-derived jet fuels must also be distilled. Distillation is a heat-intensive process that relies on fossil fuels to generate heat.

That's where Ramaswamy's lab comes in. The team is working on a way to concentrate the biofuel from fermentation broth before distillation. They are developing a process called membrane solvent extraction. It uses membranes and organic solvents to pull energy-rich biofuel compoents from a watery broth. Using this approach, they aim to reduce the energy use by 50% and water use by 25% compared to conventional distillation.

"In general terms, distillation costs energy. If we do less distillation and use membrane solvent extraction, that will save energy, and water use too," he said. It's one of many small improvements that support the DOE's holy grail: 100% biofuel by 2050. Partners GEVO, ADM and Argonne National Labs are focusing on other steps in the process of making biowaste SAF viable, such as piloting the process commercially.

Ramaswamy's research group is always looking for excellent students to join the lab. It is the students who do the day-to-day lab work that make these discoveries possible. It's also a great opportunity for undergraduate, graduate students and post-doctoral researchers. "They are the ones doing the actual work. the nitty gritty of making samples, collecting data, planning and running the experiments, analyzing the results - everything to make the research succeed."

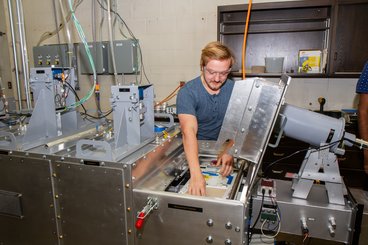

PhD candidate Koushik Sampath has been there since 2021. "It's the best decision I've taken," he said. After completing graduate coursework in biomass conversions, thermodynamic and heat transfer concepts at the University, he joined the paper drying project. He not only designs the experiments, but also designed the equipment to run them, right down to the placement of each nut and bolt. With degrees in chemical engineering and BBE, he is confident he will find a job doing research for industry after graduation. "It's a broad field. There are a lot of things that need to be done," he said.

To build that pipeline of future students, Ramaswamy and his team run yearly workshops for high school STEM teachers on bioenergy technologies. This effort is being led by Professor Ulrike Tschirner in BBE. The teachers pass the knowledge on to their students to spark an interest in STEM fields. He said, "All the climate change challenges need scientists and engineers to work on them, so we need students with good math and science backgrounds to take them on."

Decarbonization Removing fossil fuels from industrial processes and from our daily lives. Example: Manufacturing uses fossil fuels to acquire raw materials, build and run factories, manufacture the products, make packaging and deliver products to users. |